DataFlue System The System for Data Centers you Trust

Somos Jeremias

Líder mundial en el cálculo, diseño, fabricación e instalación de soluciones de extracción para sistemas de respaldo de energía en Centros de Procesamiento de Datos

Somos el único productor con suficiente capacidad de producción para cumplir con los plazos de entrega exigidos por el sector de Centros de Procesamiento de Datos. Jeremias proporciona productos de la máxima calidad para asegurar un rendimiento y una seguridad óptima.

60 países

60 países

50 años de experiencia

50 años de experiencia

10 plantas de producción

10 plantas de producción

1800 trabajadores

1800 trabajadores

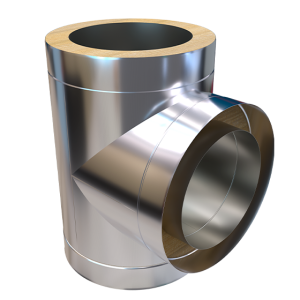

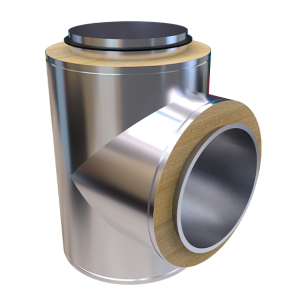

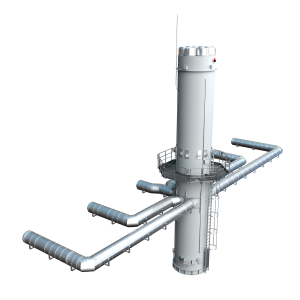

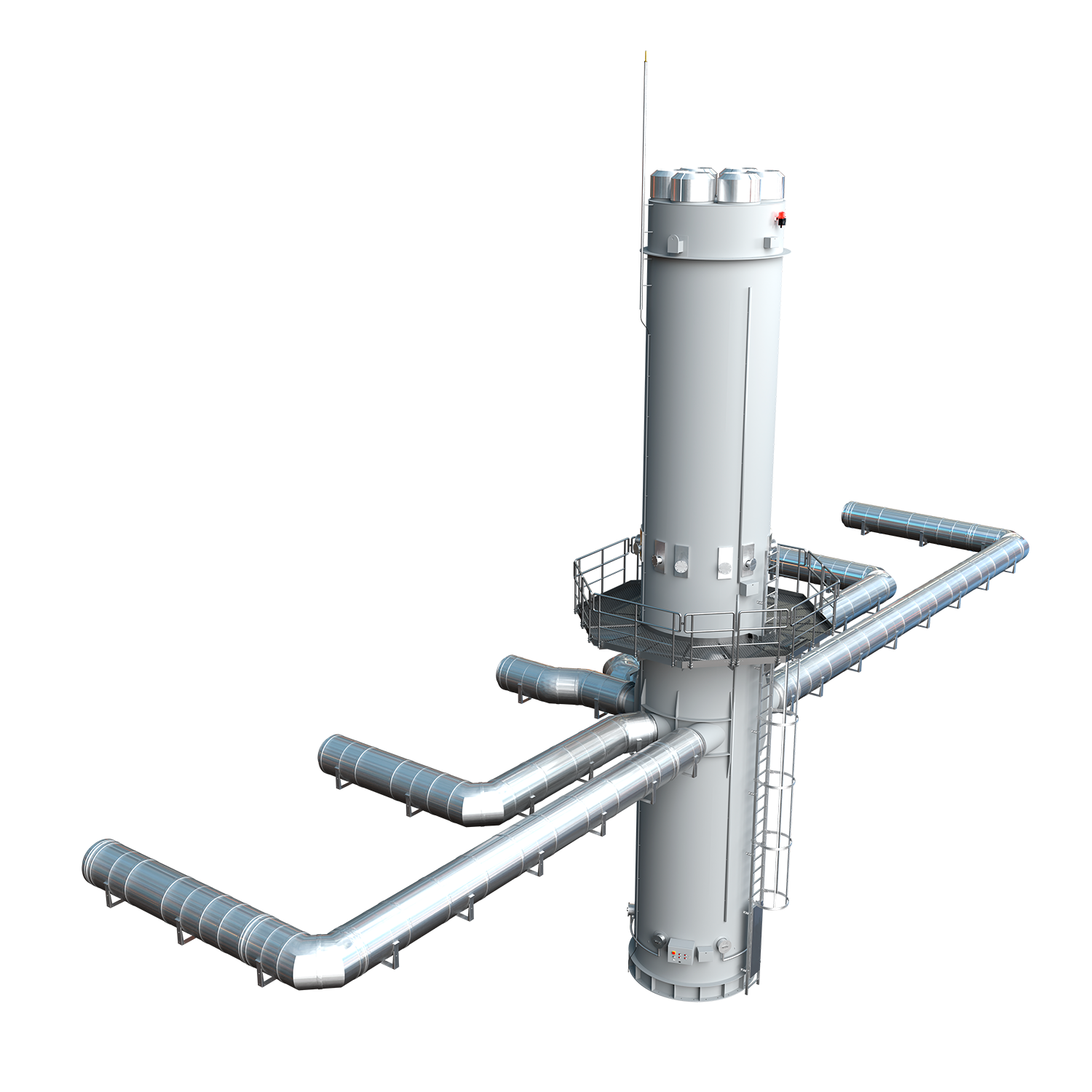

DataFlue System

El DataFlue System es el sistema de chimeneas modulares metálicas más instaladas del mundo , contando con alrededor de 1500 proyectos en 60 países.

Estanqueidad de Alta Presión

Estanqueidad del conducto interior a alta presión de hasta 15.000 Pa, asegurando un rendimiento y seguridad excepcionales.

Preaislado

Equipado con un mínimo de 50 mm de lana mineral rígida de alta densidad, el sistema puede soportar temperaturas de trabajo de hasta 600 ºC.

Prerevestido con Acero Inoxidable

El sistema está prerevestido con acero inoxidable, ofreciendo una garantía contra la corrosión de 25 años, lo que garantiza una durabilidad a largo plazo.

Modular y Prefabricado

Su naturaleza prefabricada permite una implantación modular, lo que reduce significativamente el tiempo de construcción y mejora la precisión de las instalaciones.

Soluciones

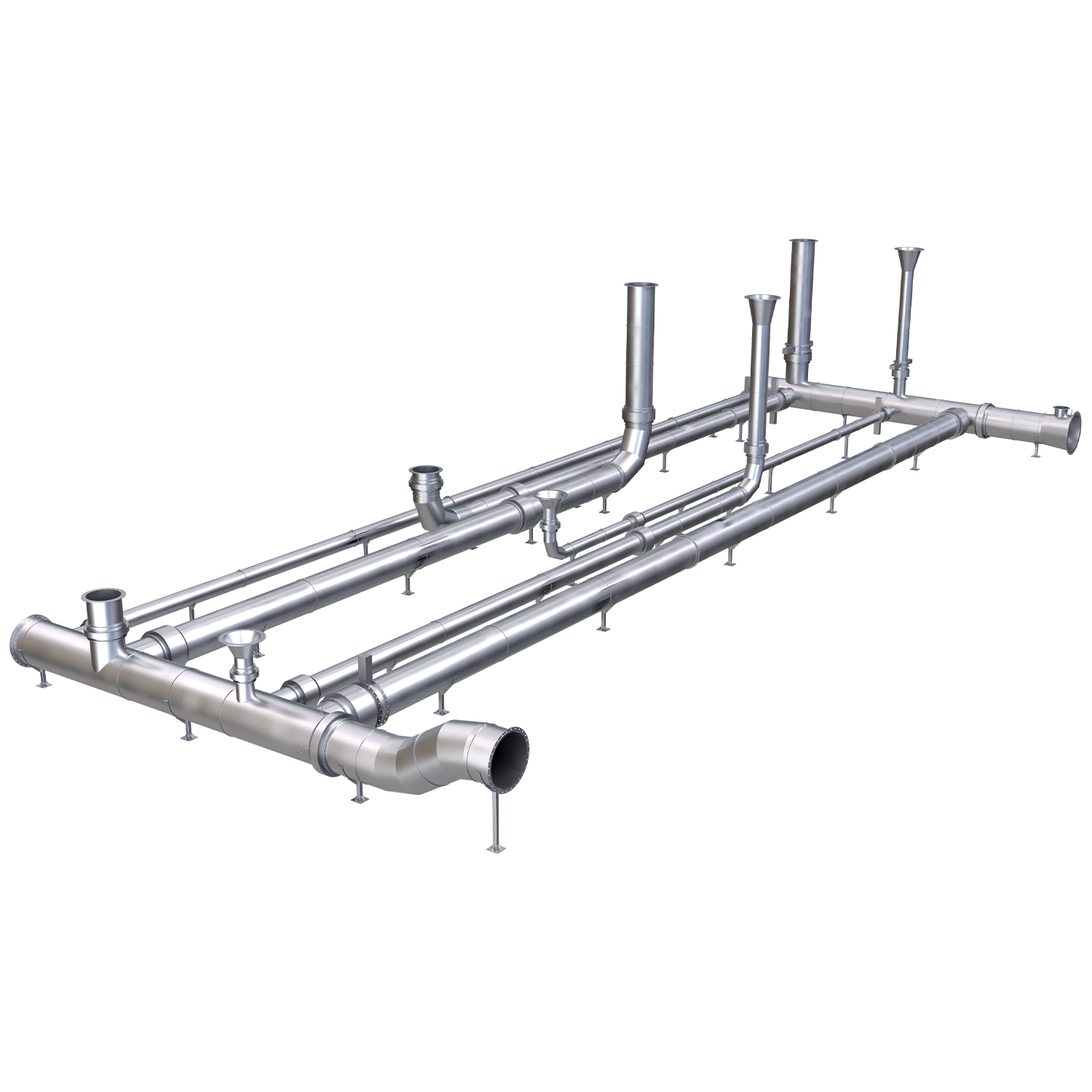

- DW-KL 50

- DW-FS 50

- Conductos de espesor variable

-

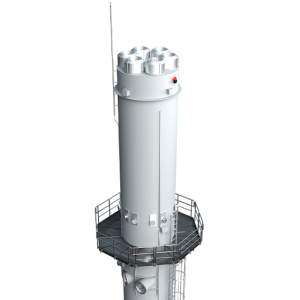

Chimeneas Autoportantes

- FSA

- FSA-X

- Estructuras

Proyectos por todo el mundo

Descubre nuestros

Casos de Éxito

Conviértete en nuestro socio

Programa de Socios de Jeremias

El Programa de Socios especializado de Jeremías para los agentes de la cadena de valor de los Centros de Procesamiento de Datos.

Beneficios de instalación

Personaliza tu proyecto desde el inicio hasta el final.

Herramientas y tecnología

Acceso a herramientas de cálculo y diseño de última generación.

Ventas y marketing

Marketing, ventas y soporte técnico especializado.

Formación y certificación

Acceso exclusivo a programas de formación especializados.

Gestión de socios y soporte técnico prioritario

Reconocimiento y comunidad

Invitación a eventos exclusivos.

Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy Conviértete en nuestro socio hoy

Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto Háblanos acerca de tu proyecto